Need reliable and efficient services? We are here to support you!

Our expertise meets your needs in the development of your electronic systems. Our knowledge and efficiency propel your projects toward success.

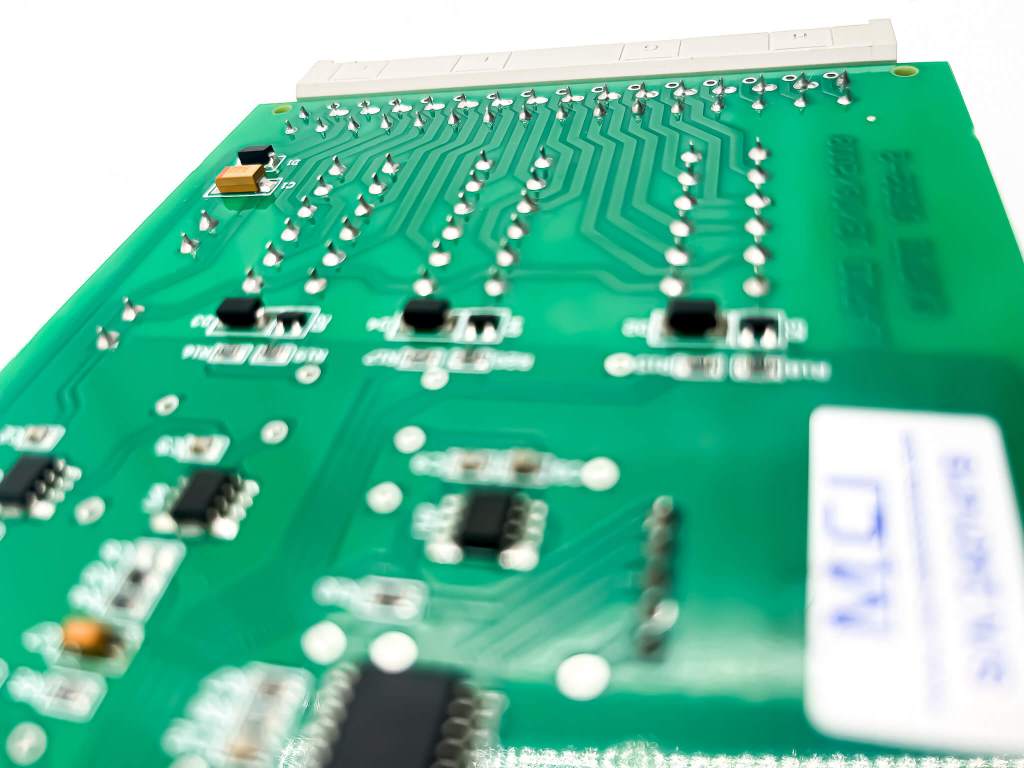

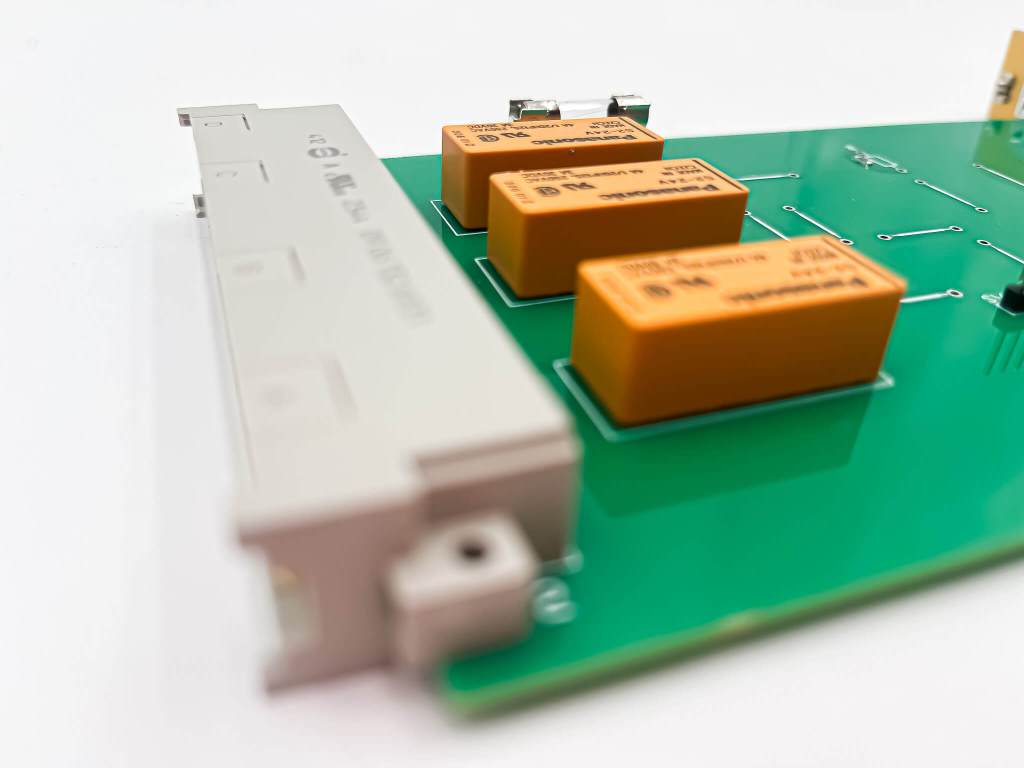

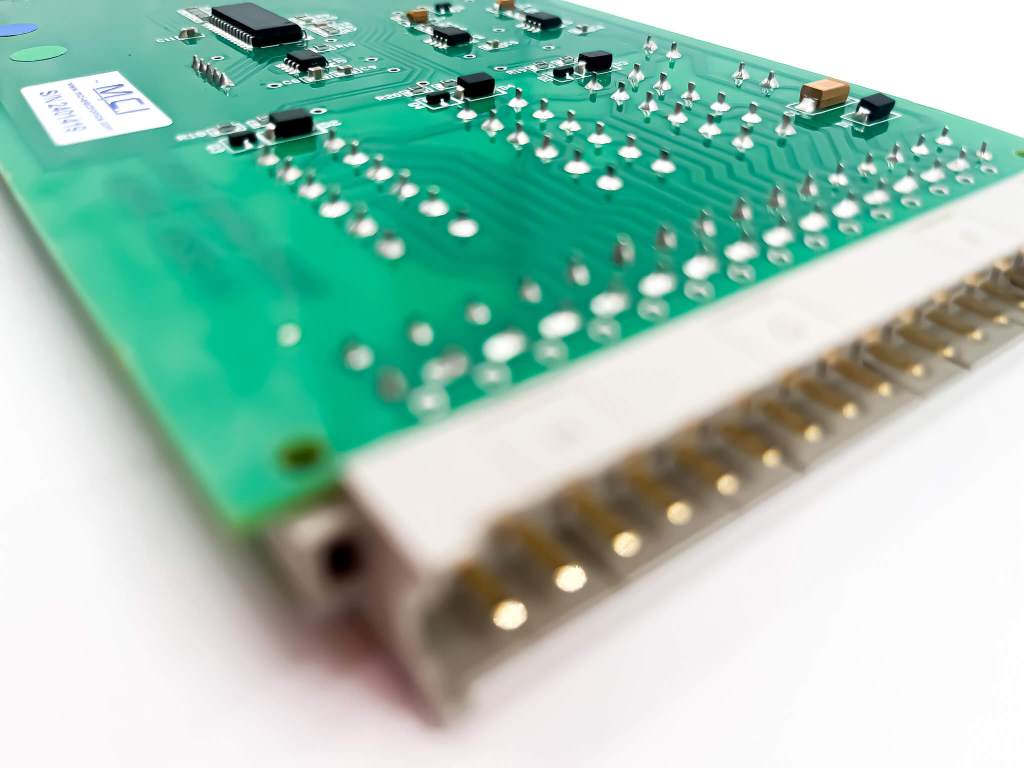

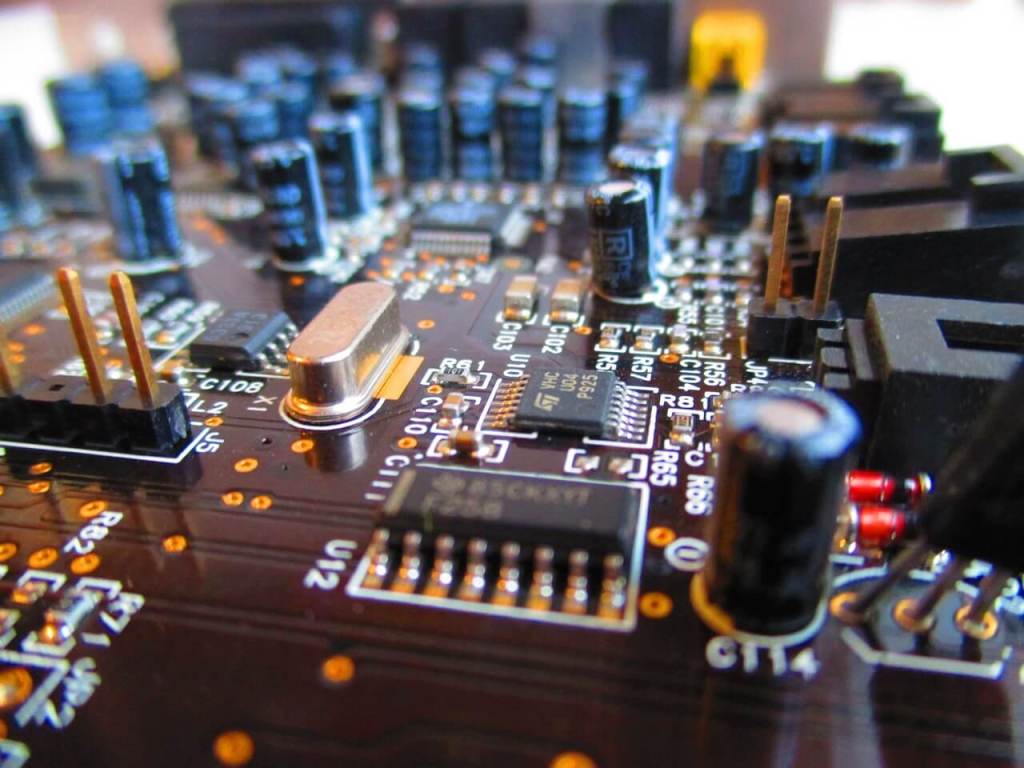

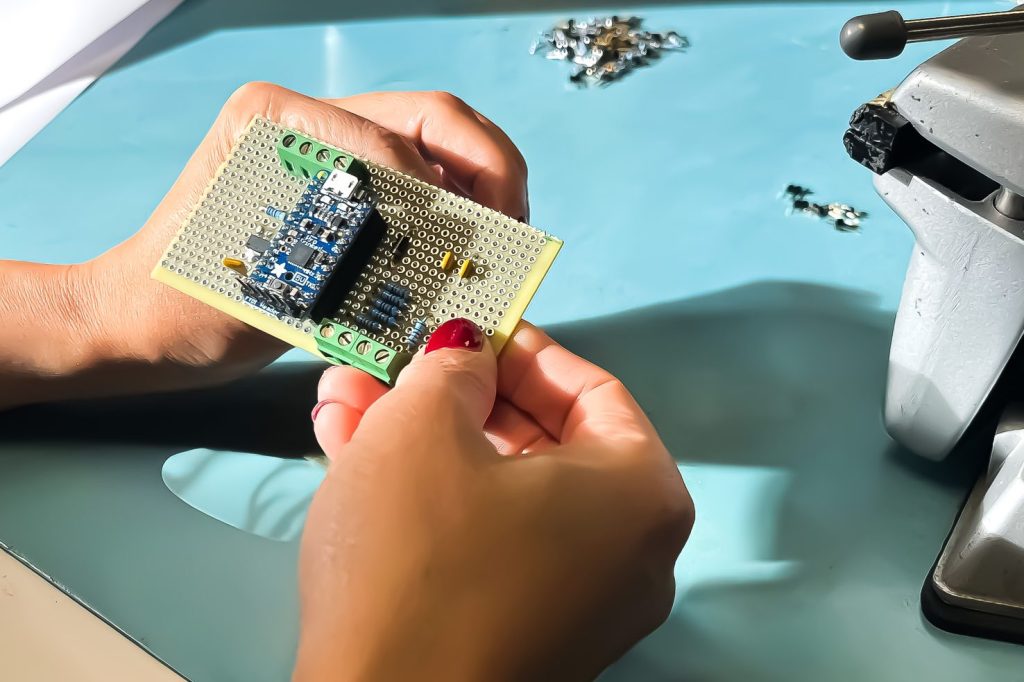

MCI is your technical backup, offering dedicated support and after-sales service to ensure the success of your projects. MCI supports you in the development and realization of your electronic solutions for the manufacturing and rework of your custom boards. Our expertise allows us to assemble all types of through-hole or SMD components manually or semi-automatically on your electronic boards, while guaranteeing full compliance with requirements and current standards. The flexibility and adaptability of our services, along with our expertise, enable us to offer the first parts within 24 to 48 hours, depending on the complexity of the project, from prototype to small and medium production runs.

Thanks to its numerous suppliers, MCI is able to supply you with all the components and PCBs.

Our different types of boards:

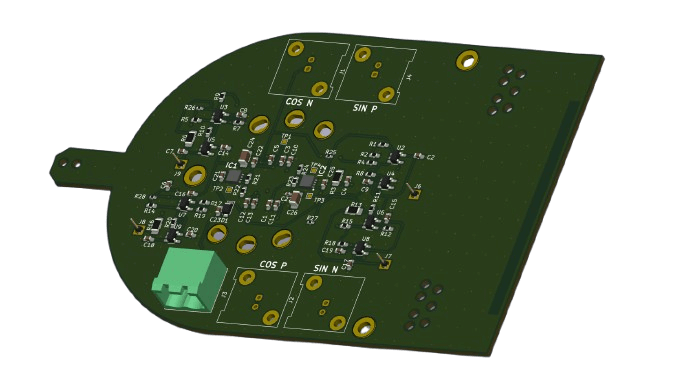

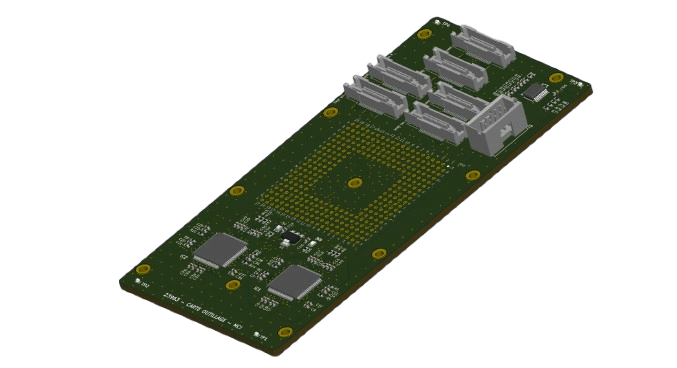

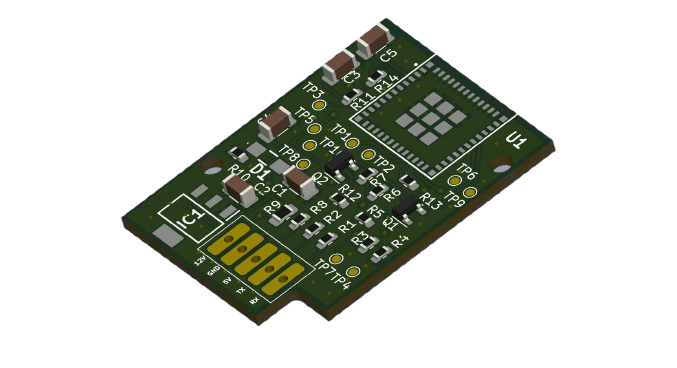

Custom-made board

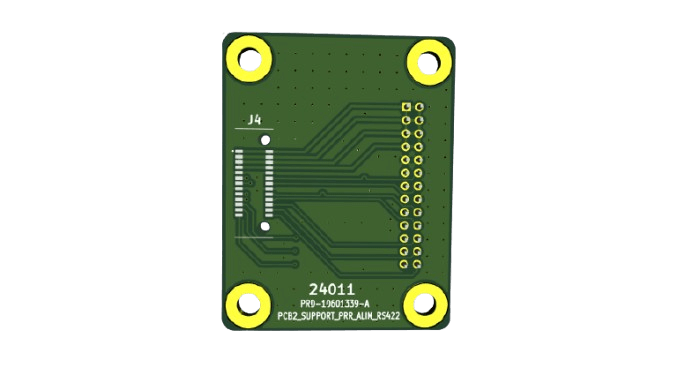

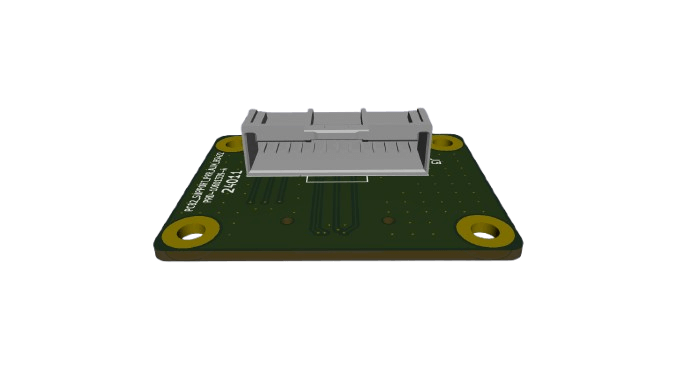

Interface/adapter board

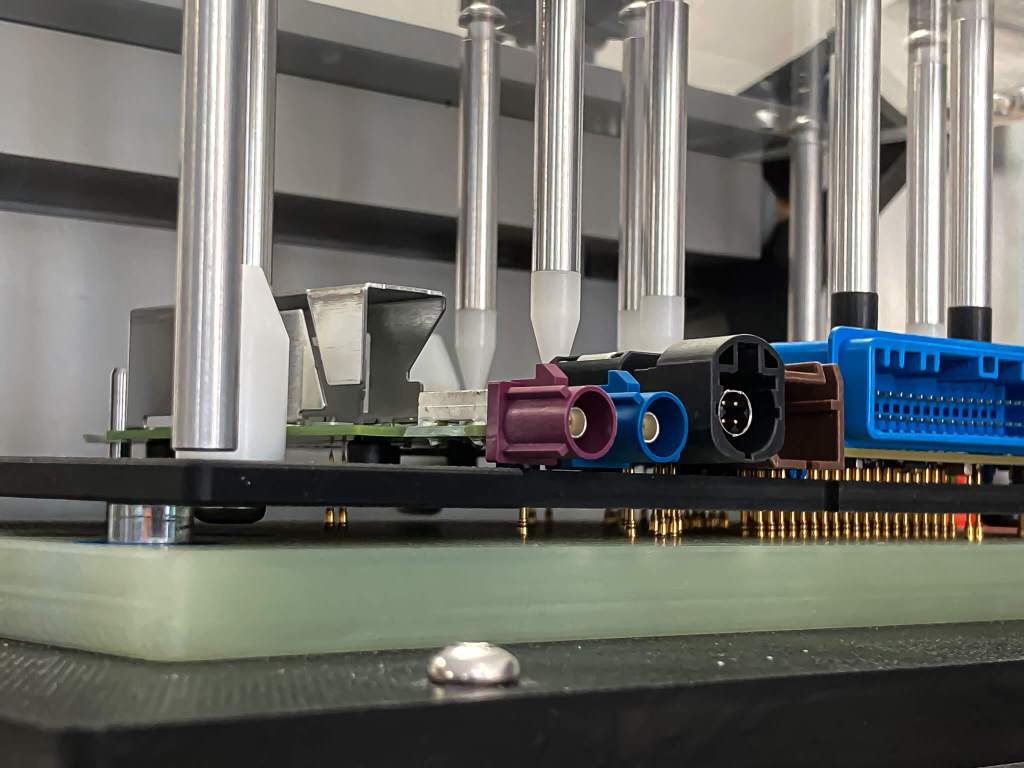

Pin bed board

Custom-made board

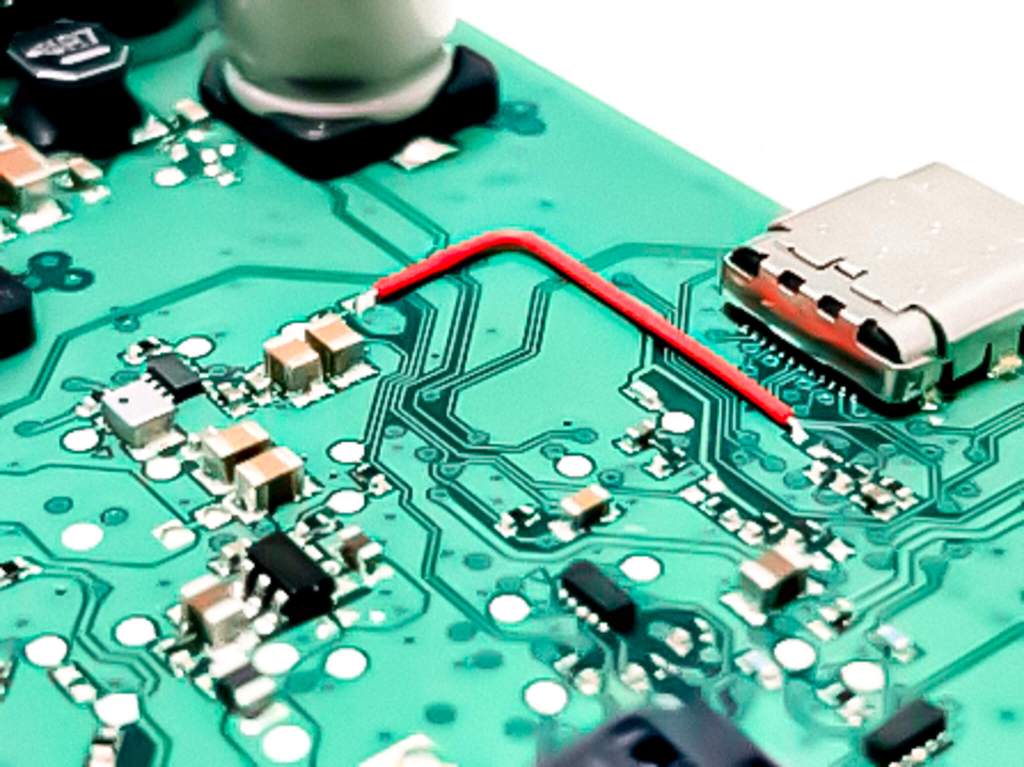

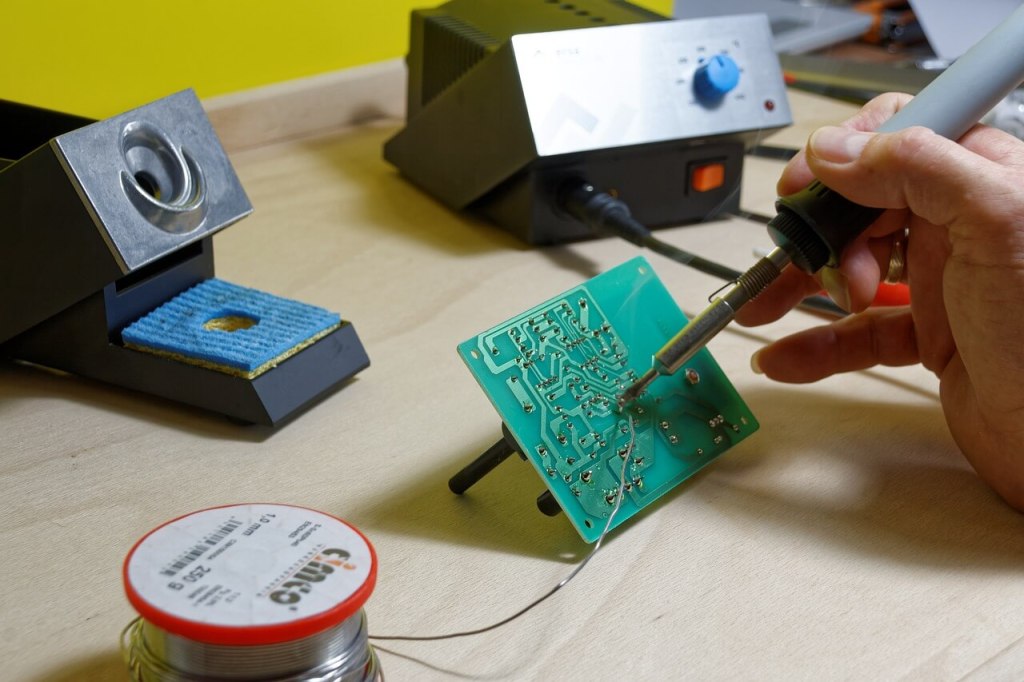

MCI is often called upon for board modifications such as:

- Adding components

- Changing components

- Wired routing modifications (rework)

- BGA replacements

Through its co-creation model, MCI supports you in bringing your project to life and ensuring its success, as it is at the heart of our concerns.

Why choose MCI electronic boards?

- Miniaturization and Compactness

- Performance and Reliability

- Service Customization

- Simplified Development Process

- Ethics and Eco-responsibility

- Modular Design

- Versatility

- Technical Expertise

- Logistical Advantages

The features of our electronic boards:

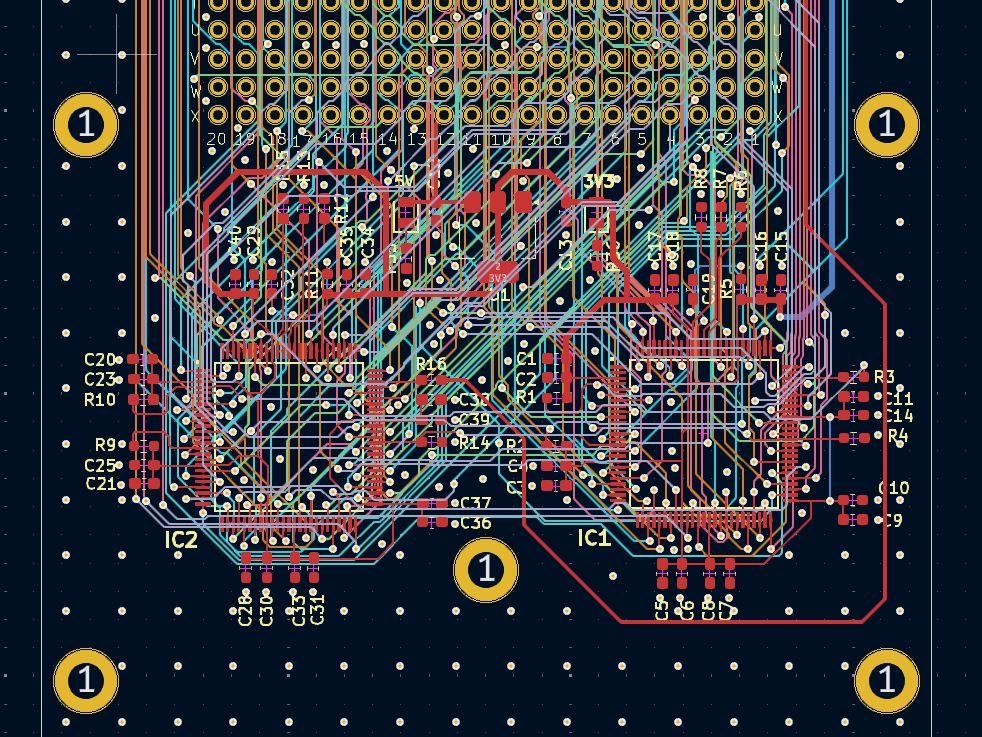

Technologies mastered:

Base material:

- Epoxy resin (FR4)

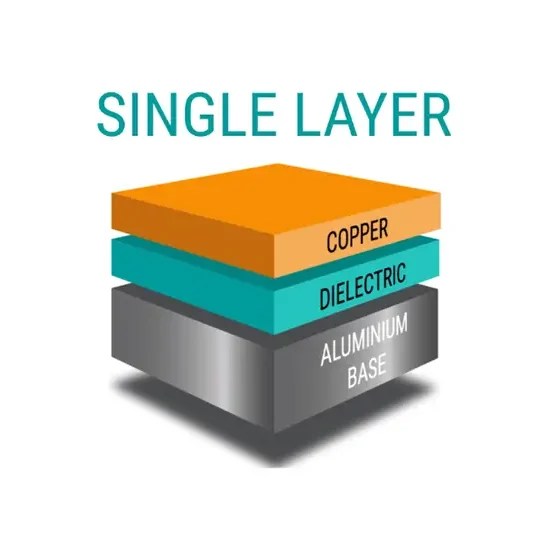

Layers:

- Single-layer boards

- Double-sided boards

- Multilayer boards

Technologies :

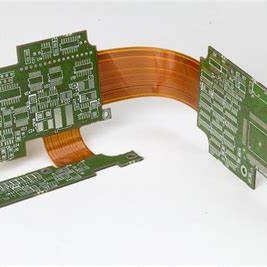

- Rigid boards

- Flexible boards

- Rigid-flexible boards

- SMT boards (Surface-Mount Technology)

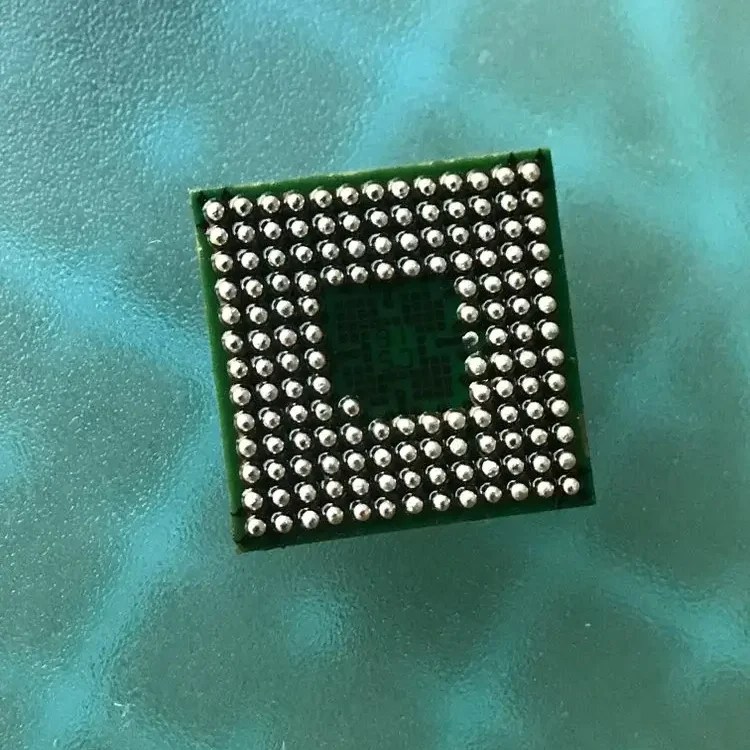

BGA, QFN, LGA

PCB Multicouche

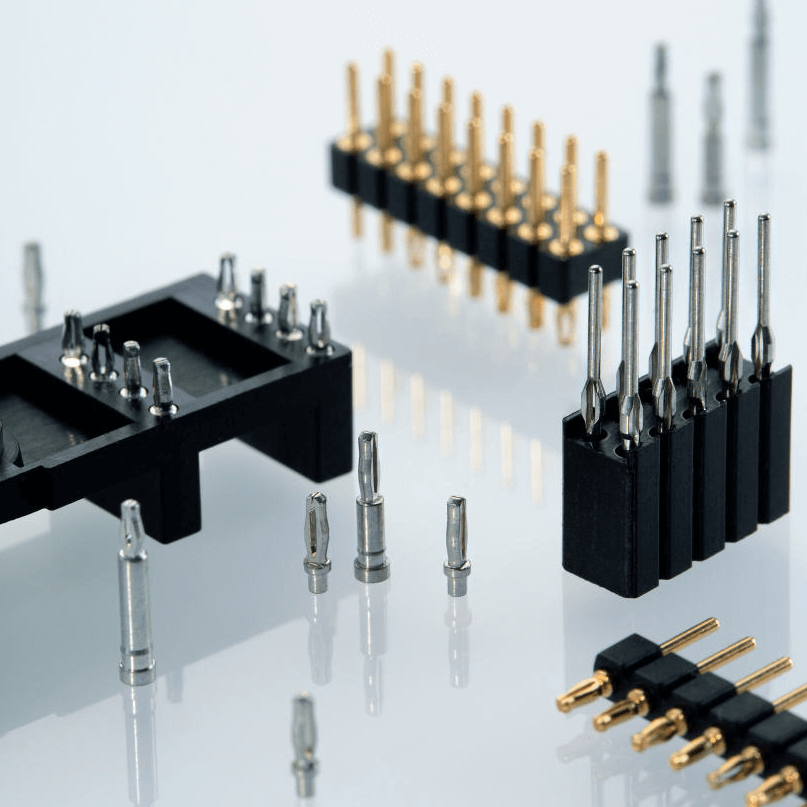

Composant press-fit

PCB SMI

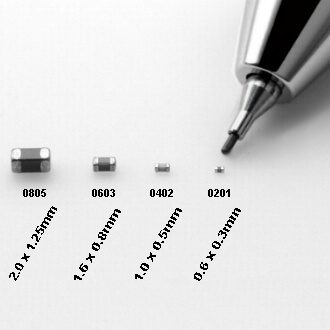

CMS jusqu’à 0201

PCB Flexi-rigide

Prototyping and production from small to large runs:

- Rapid prototypes: Manufacturing prototypes to validate concepts before production.

- Small, medium, and large runs: Flexible manufacturing to meet the needs of specific or low-volume projects.

- Customization: Zone assembly, Leaded or RoHS soldering, Partial delivery options.

Cost reduction and performance optimization:

- Material savings: Optimized design to reduce costs while ensuring durability.

100% Guarantee, Technical support

The methods of electronic board assembly:

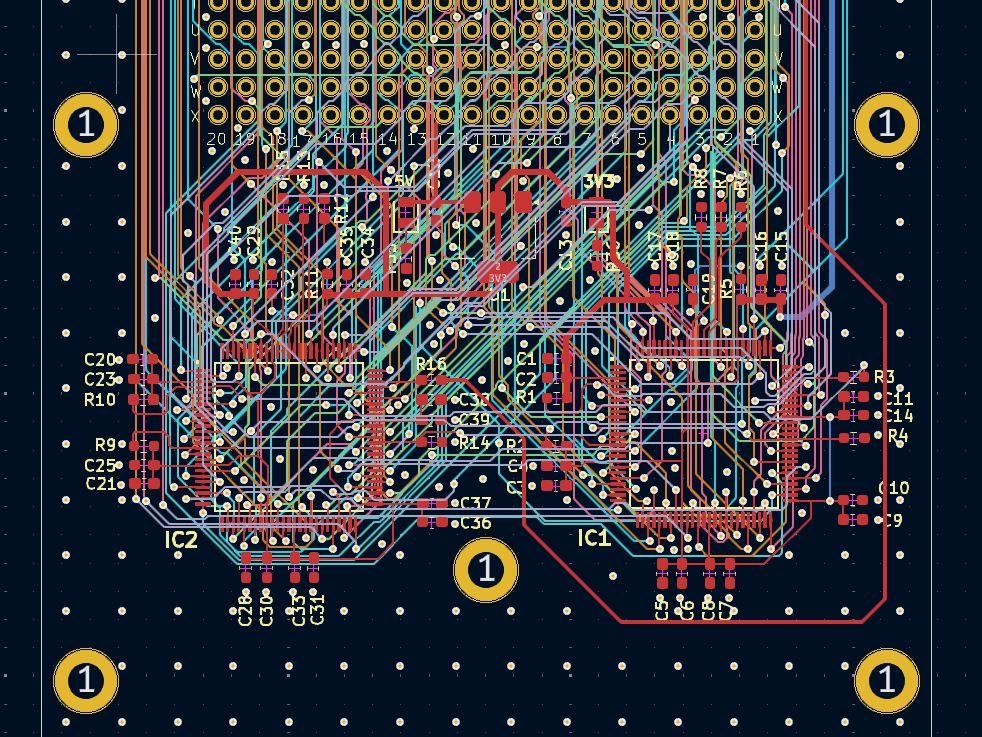

Step 1: PCB manufacturing

Design and production of the printed circuit board (PCB)

Step 2: Application of solder paste

Depositing solder paste onto the PCB pads to accommodate SMD components (Surface-Mounted Devices).

Step 3: Placing the components

Automatic or manual placement of electronic components on the board.

Step 4: Soldering

Reflow process for SMD components or wave soldering for through-hole components (THT).

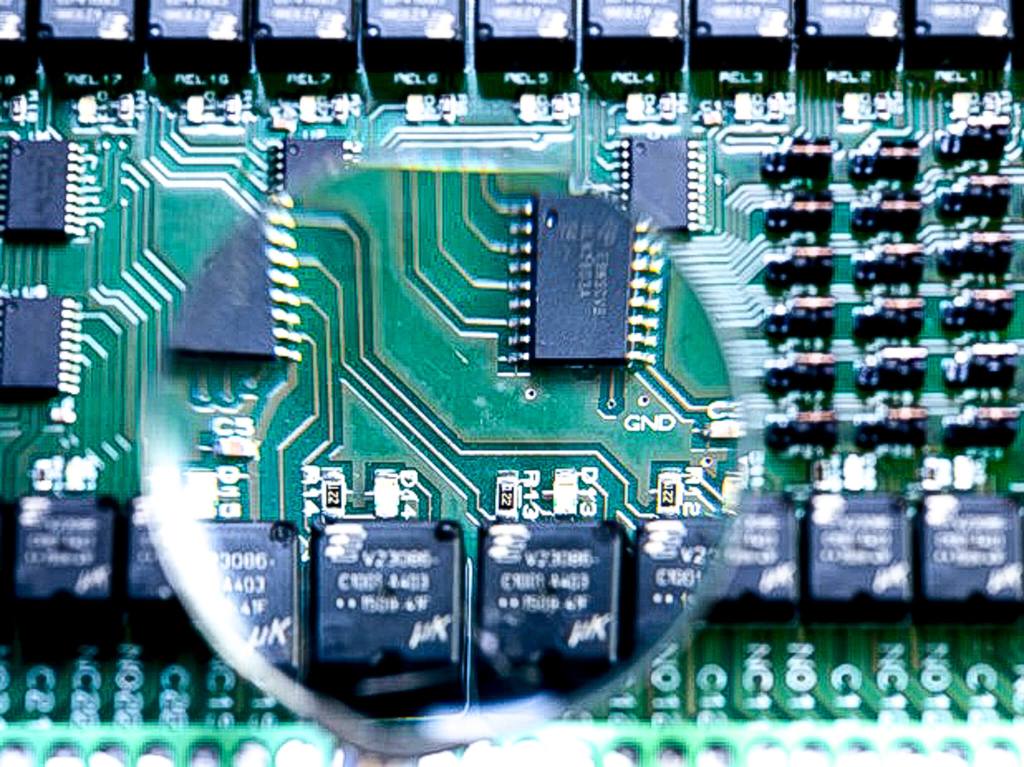

Step 5: Inspection and testing

Quality control

Step 6: Final assembly

Adding the final elements (connectors, enclosures, protection) and final testing before delivery.

MCI Electronics understands the importance of your time, and each project is managed optimally.

Our production is carefully planned.

Routing

Prototyping

Custom electronic board, electronic board manufacturing, electronic board design, electronic board assembly, electronic board testing, electronic board prototyping, electronics industrialization, electronic board subcontractor, PCB routing, electronic integration, reliable electronic board, industrial electronics quality, electronic board quality control, electronic board performance, electronic board certification, embedded electronics reliability, compliance with electronic standards, electronic system safety, electronic board for industry, industrial embedded electronics, electronic board for automotive, industrial electronic solutions, electronics for special-purpose machines, electronics for critical systems, electronic subcontracting partner, electronic board expert, electronics subcontracting in France, industrial electronics services, electronics design office, electronic board supplier