Need reliable and efficient services? We are here to support you!

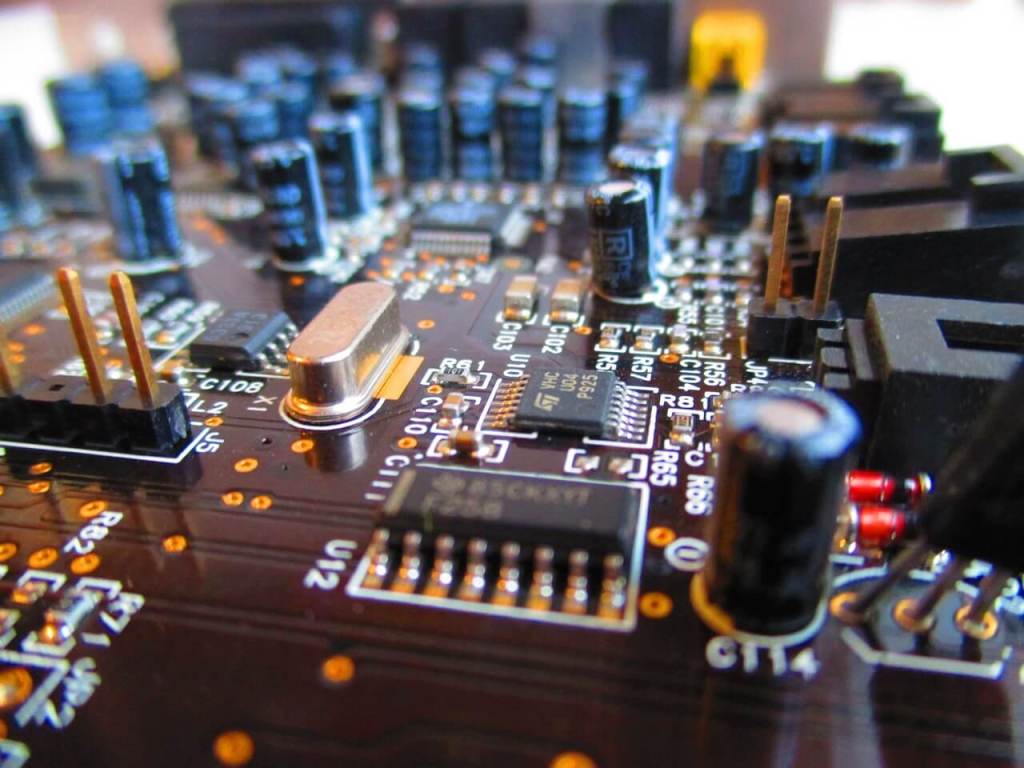

Our expertise meets your needs in the development of your electronic systems. Our knowledge and efficiency drive your projects towards success.

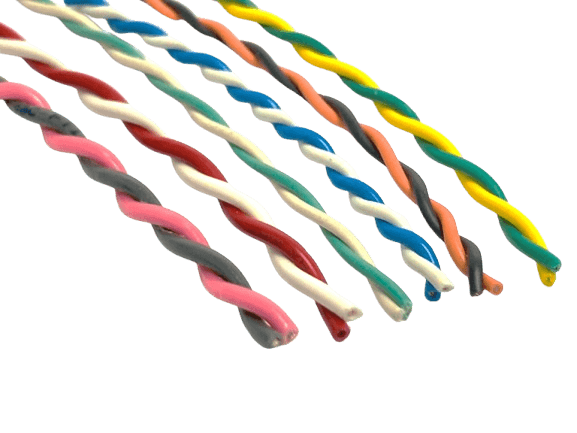

MCI, an expert in the design and development of your custom electronic solutions, manufactures your twisted wires for optimal signal transmission in differential pairs. For all your electronic applications, MCI ensures performance, robustness, and reliability.

The flexibility and adaptability of our services, along with our expertise, allow us to offer you the first prototypes within 24 to 48 hours, depending on the project’s complexity, from prototype to small and medium series.

- Excellent resistance to interference.

- Exceptional longevity.

- Suitable for all industries.

Packaging starting from 1 meter.

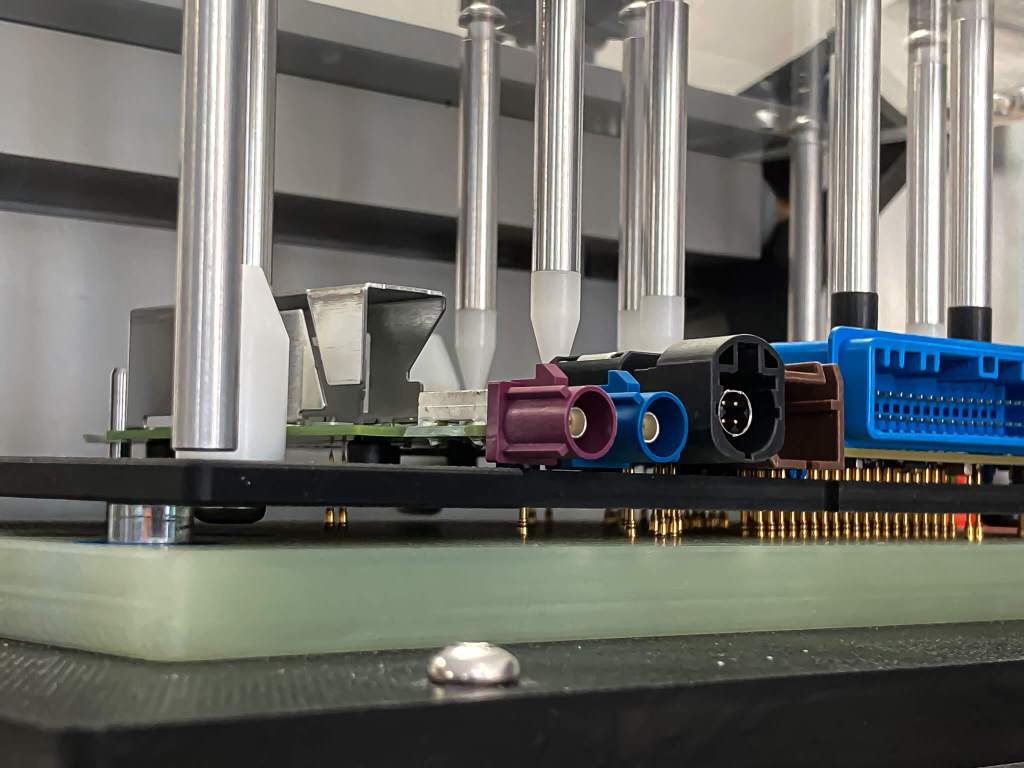

MCI is your support for technical advice and assists you in choosing the connectors and wire technology, as well as in creating your specifications. Our speed and efficiency remain our strengths.

Why choose MCI twisted wires:

- Improved data transmission

- The twisting of the wires helps reduce interference

- Twisted wires are more resistant to stress

- Thermal management and heat dissipation

- Long-term cost reduction

- Organization and aesthetics of your wires

- Versatility of use

- Compliance with standards and safety

We manufacture your custom twisted wires. The wire is twisted without twisting by two or more conductors wrapped around each other, which prevents the wires from separating after cutting and ensures an equal length of both conductors.

Reducing electromagnetic interference, thus ensuring better transmission quality.

The characteristics of our twisted wires:

Configuration and Structure

- Twisted pairs: Assembly of two or more wires twisted together to reduce electromagnetic interference.

- Twist length (pitch): The distance between each twist, optimized for specific performance (data transmission, reduction of EMI).

- Multistrand or solid core: Available in flexible (multistrand) or rigid (solid core) versions depending on installation needs.

Manufacturing Materials

- Conductors: Bare copper, tinned, or silver-plated for better conductivity and corrosion resistance.

- Insulation: PVC, polyethylene, Teflon (PTFE), or silicone, providing protection against temperature, humidity, and chemical agents.

- Optional shielding: Metal foils or braids for additional protection against interference.

Electrical Performance

- Transmission capacity: Suitable for high-frequency signals and low currents.

- Controlled impedance: Ideal for network applications (Ethernet, telecommunications).

- Electrical resistance: Low resistance to minimize signal loss.

Customizable Options

- Insulation colors: To facilitate wire identification.

- Marking: Custom numbering and labeling for easy cable management.

- Custom length: Available in reels or precise cuts according to the customer’s needs.

Physical and Mechanical Properties

- Available diameters: Several gauges (AWG) to suit specific power and signal requirements.

- Flexibility: High flexibility for complex or mobile installations.

- Mechanical resistance: Robust design to withstand physical stress, vibrations, and friction.

Thermal Characteristics

- Temperature range: Resistance to extreme temperatures, typically from -40°C to +125°C depending on the materials.

- Thermal dissipation: Optimized structure to prevent overheating of the conductors.

Protection and Safety

- Reinforced insulation: Prevention of short circuits and electrical hazards.

- Resistance to external agents: Protection against moisture, chemicals, and UV rays for outdoor applications.

- Compliance with standards: Adherence to CE, UL, and RoHS standards to ensure safety and reliability.

Cable assemblies and harnesses

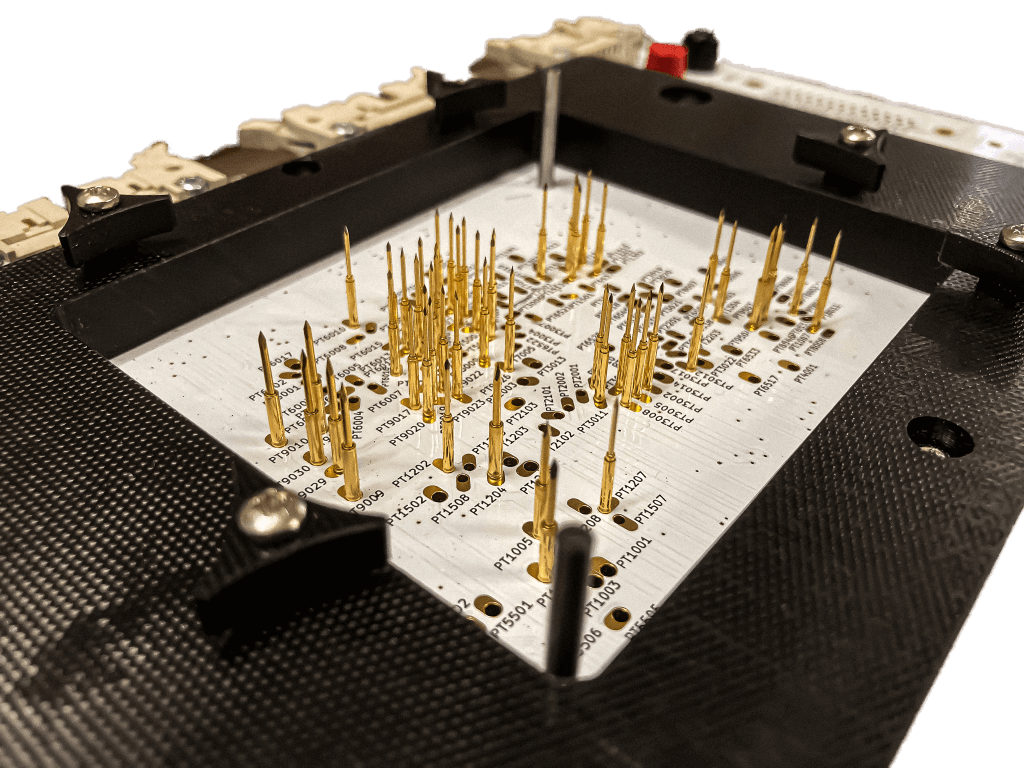

Nail beds

Twisted wire manufacturing, twisted wires for electronics, shielded twisted wires, twisted wire cabling, tinned copper twisted wire, twisted wire workshop, twisted wire subcontractor for electronics, custom twisted wire, twisted wires for electronic boards, twisted cabling for embedded systems, twisted cables for electronic connectors, twisted wires for low-signal transmission, EMI/RFI shielding cabling, twisted cables for sensitive equipment, wire cutting and twisting, twisted cable preparation, crimping of twisted cables, supply of custom twisted wires, harness assembly with twisted wires, multi-strand twisted wires, shielded / unshielded twisted cables, manual or automatic twisting, tinned copper twisted wire, twisted wires with insulating jacket, workshop for custom twisted cable manufacturing, where to find a twisted wire subcontractor, twisted cabling for industrial environments, interference-resistant twisted cabling solutions, twisted cable specialist for embedded electronics