Need reliable and efficient services? We are here to support you!

Our expertise meets your needs in the development of your electronic systems. Our knowledge and efficiency drive your projects toward success.

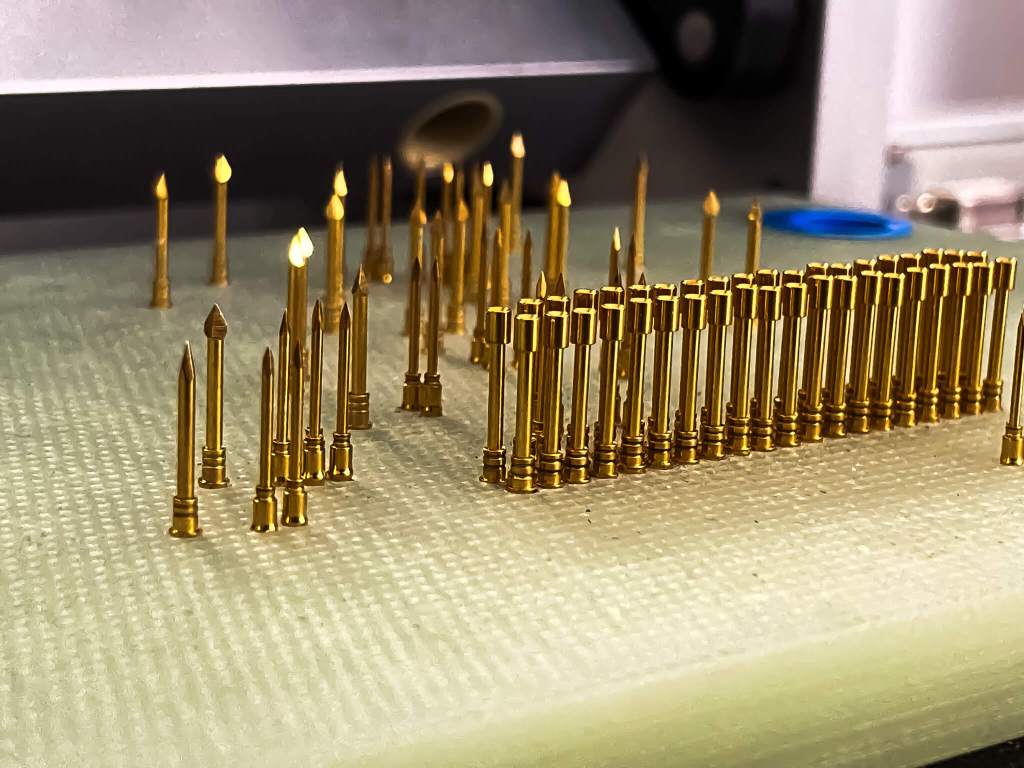

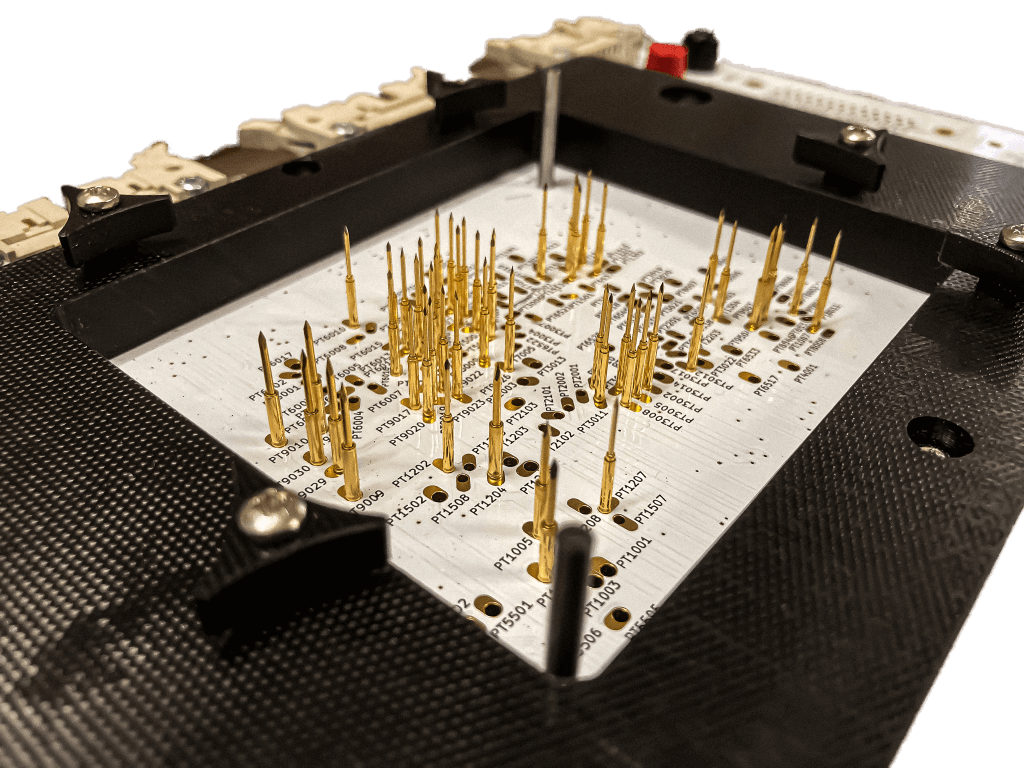

MCI supports you in the development and realization of your electronic solutions for the manufacturing and repair of your pin beds, MCI’s flagship product. Our expertise allows us to carry out machining and engraving through our mechanical team. Wiring is also done in-house by our team. This guarantees you full compliance with requirements and current standards. The flexibility and adaptability of our services, along with our expertise, allow us to offer the first parts within a timeframe of one to several weeks, depending on the complexity of the project. Through its co-creation model, MCI helps you bring your project to life and achieve its success, as it is at the heart of our concerns.

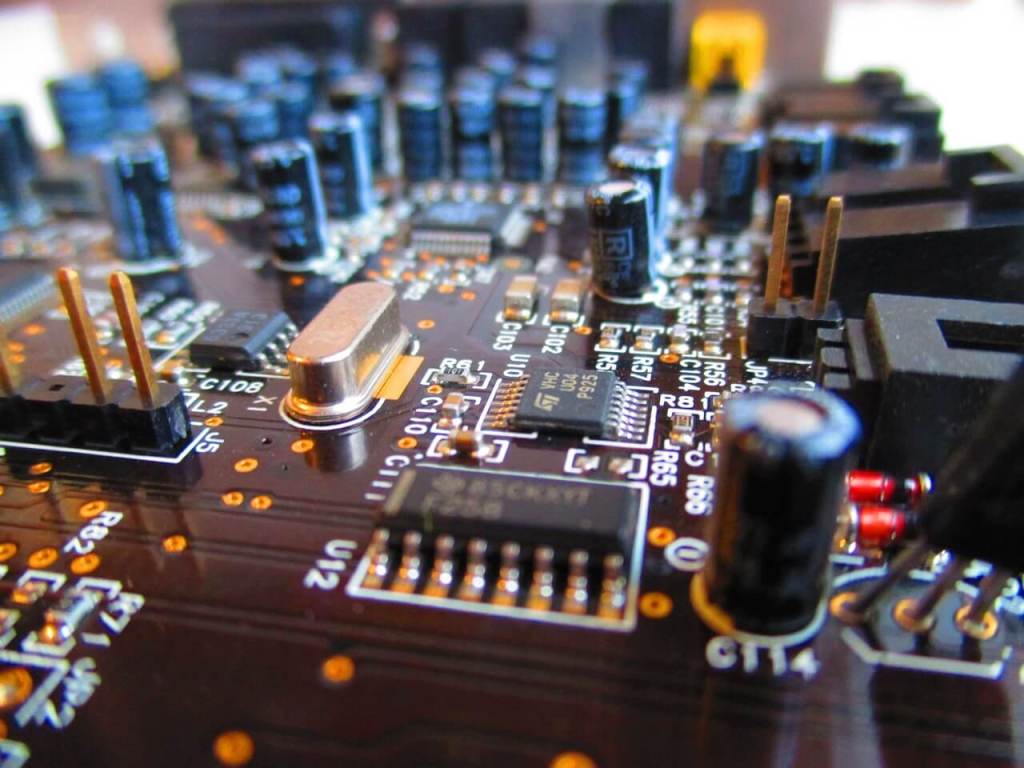

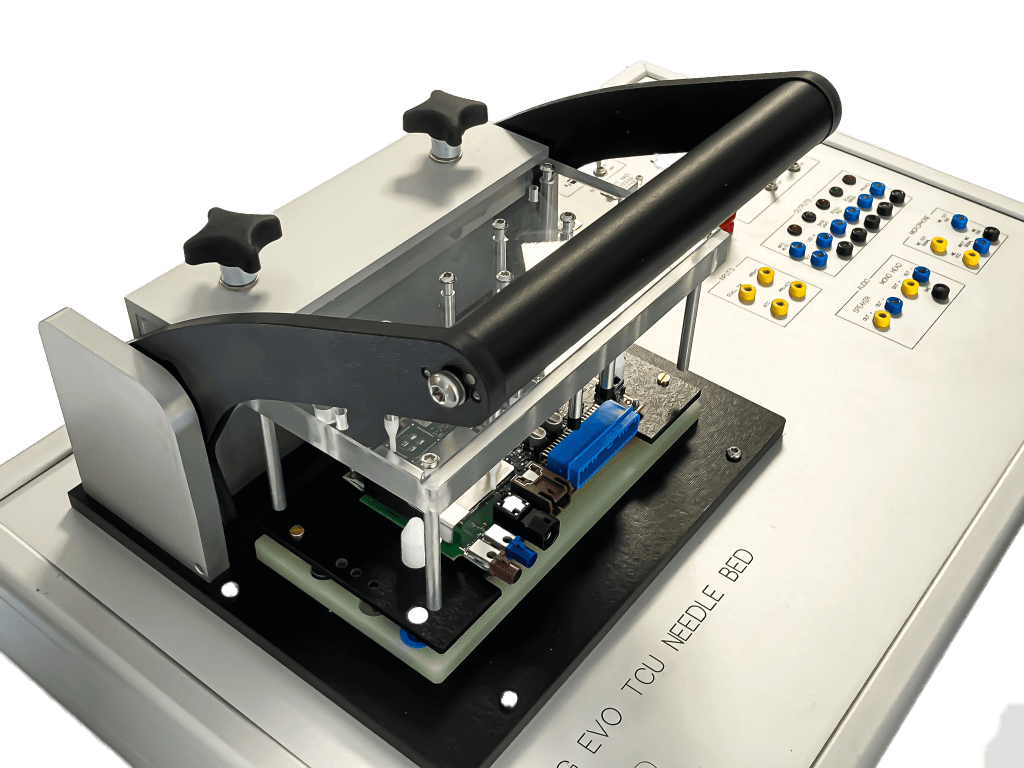

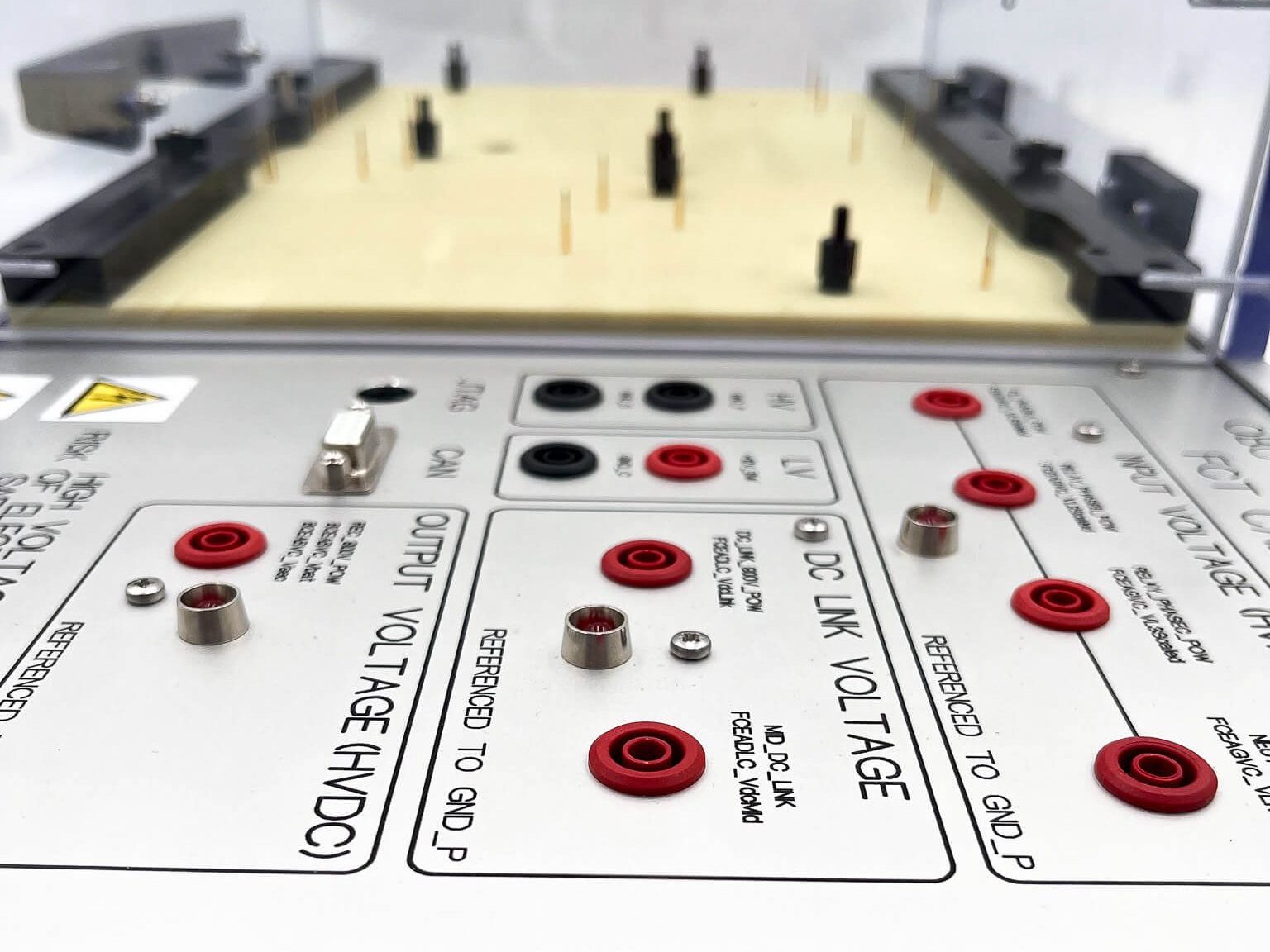

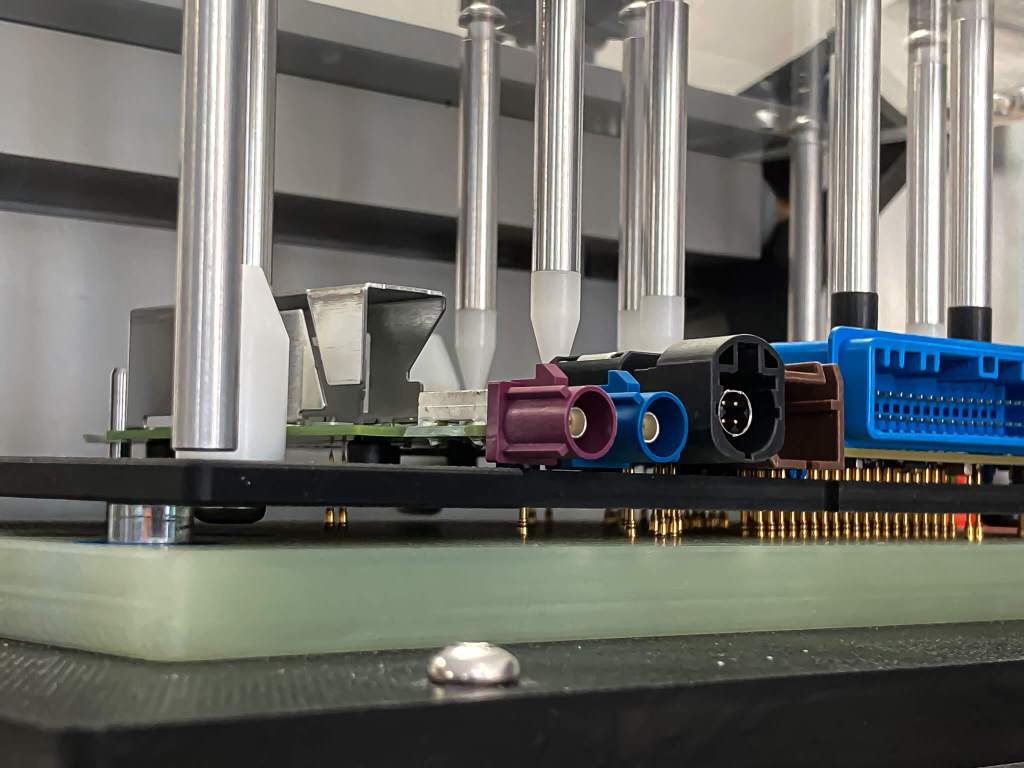

Industrial test interfaces

Industrial test interfaces are high-end, robust, and ergonomic pin beds. They are designed for repeated testing in production.

Machined pin beds

The major advantage of these pin beds is their large usable surfaces for the arrangement of connectors with a custom-made enclosure.

Machined pin beds are an ideal solution for prototyping and small production runs.

Custom-made pin beds

Custom-made pin beds allow for testing all types of boards with complex mechanics.

The design and creation of these systems are fully customized.

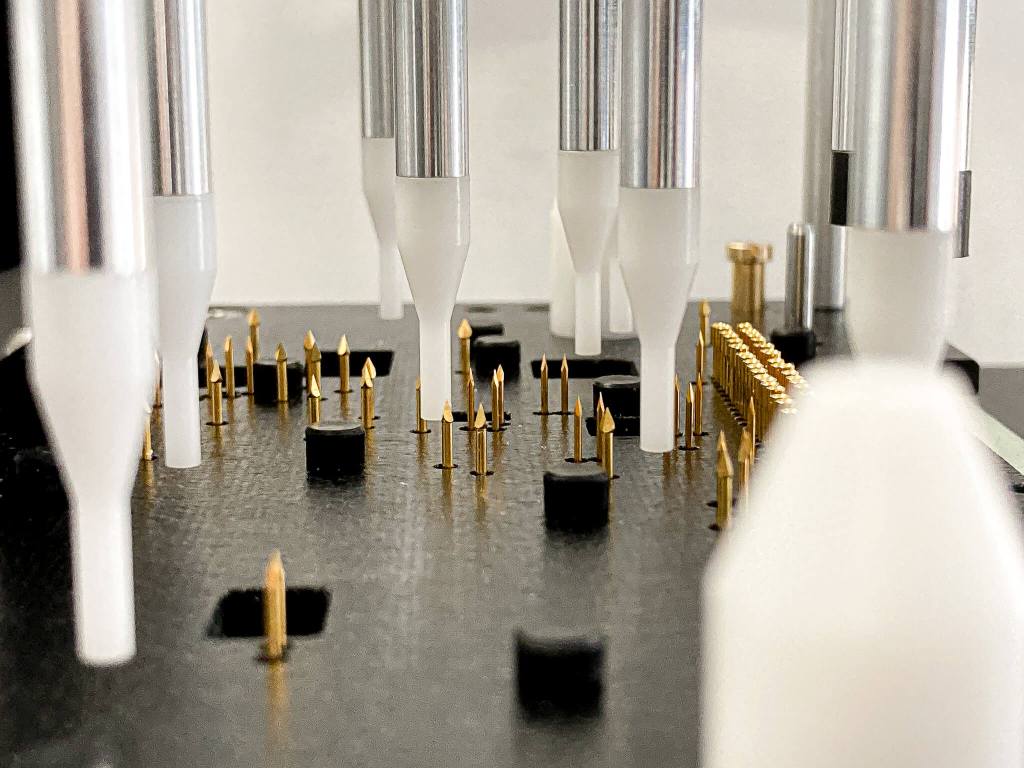

Pin beds with routing

These pin beds with integrated routing provide an optimal testing solution for your small and medium-sized electronic boards. Designed to combine precision and efficiency, they are perfectly suited to the requirements of high-volume production, ensuring increased reliability during testing and validation phases.

Technical support, 100% guaranteed!

The advantages of MCI pin beds:

- Ergonomics

- Safety

- Does not damage printed circuit boards

- Fast and repetitive testing with precision

- Time savings and reduction of quality control costs

Design and Manufacturing Process

Step 1

Study of your needs and constraints.

Step 2

Design and modeling (mechanical and electrical schematics).

Step 3

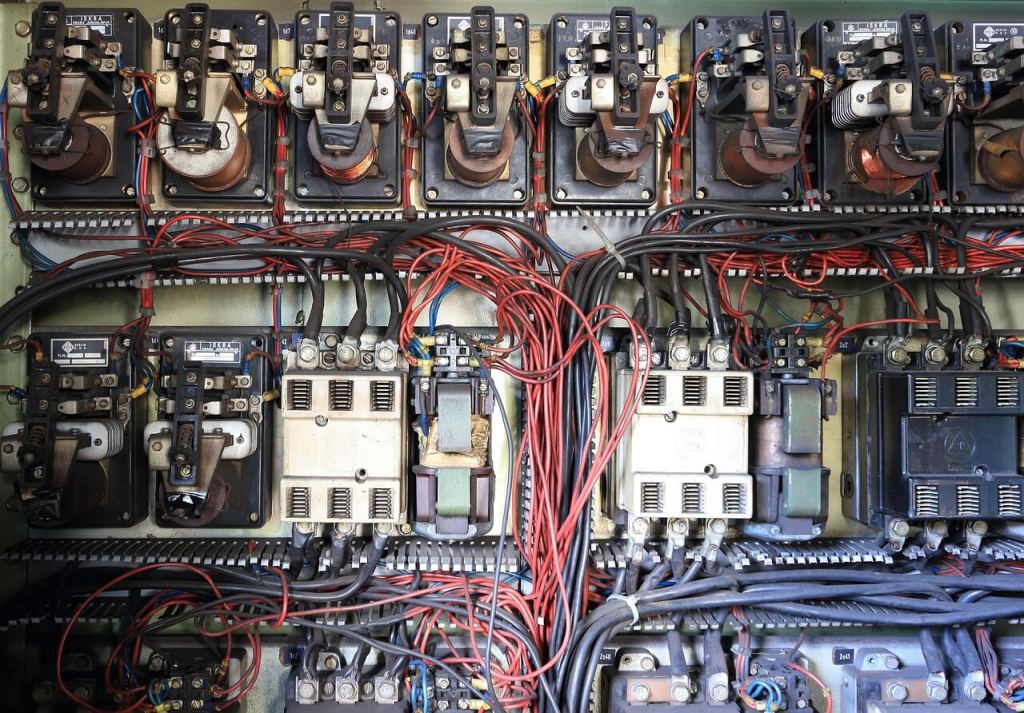

Manufacturing and internal wiring.

step 4

Testing and verification before delivery.

Step 5

Installation and commissioning on-site upon request.

The features of our pin beds:

Type of tests:

- Functional test

- Performance test

- Endurance test

- High voltage test

- Safety test

Connectors:

- Banana plug / BNC

- DIN / SUB-D / HE-10 connector

- Custom connectors

Materials:

- Aluminum or plastic enclosure

- ESD material

- High electrical resistivity insulating support

- Ground steel mechanical guides

Compatibility:

- Single-sided boards

- Double-sided boards

- Boards mounted on mechanical structures

- Panelized boards

- Multi-product testing

Types of pins:

- Standard pins

- High power

- RF

- Custom pins

- Fine pitch

Electronic bed-of-nails, bed-of-nails test bench, electronic test fixture, in-circuit bed-of-nails testing, bed-of-nails manufacturing, bed-of-nails for electronic boards, printed circuit board bed-of-nails testing, PCBA production testing with bed-of-nails, bed-of-nails test solution, custom test bench, functional validation with bed-of-nails, electrical testing via contact points, automated bed-of-nails testing, high-density bed-of-nails, testing tool for electronic boards, bed-of-nails for industrial series, maintenance and repair of bed-of-nails systems, ICT (In-Circuit Test) with bed-of-nails, performance and reliability of test benches, electronic test fixture design