Checklist: Choosing the Right Subcontractor for Your Electronic Circuit Boards

In the electronics industry, quality is a fundamental lever of performance for any company. An electronic subcontractor must meet the high quality standards demanded by the market. With over thirty years of expertise, MCI has built strong and lasting partnerships with its suppliers and collaborators by designing high-quality electronic and mechanical solutions. The goal is clear: to work closely with all stakeholders in the supply chain to optimize procurement, ensure the reliability of embedded systems, and effectively meet customer requirements.

Quality at the Heart of Electronic Circuit Board Design

A Rigorous Selection of Components

Working with a subcontractor that has a network of certified suppliers is essential to ensure the reliability of the components used. This level of rigor makes it possible to meet the strict standards of the industry while ensuring regulatory compliance throughout the entire supply chain. It is a complex and often time-consuming task, but one that is crucial to ensuring the longevity and reliability of electronic equipment.

Continuous Inspections and Testing

Each electronic circuit board undergoes meticulous quality inspections at every stage of its manufacturing process. These checks help identify potential defects early on, thereby reducing the risk of failures and the costs associated with possible non-conformities during production.

Performance: Designing Adapted and Optimized Electronic Circuit Boards

Adaptation to Specific Needs

The services offered by a subcontractor must be fully customized to meet the technical and environmental constraints specific to each project. It is in this ability to provide tailored solutions that the true added value of an industrial partner lies.

Optimization of Electrical and Mechanical Performance

At MCI, this performance requirement is reflected in dual expertise: electronic and mechanical. The electronic design office handles the routing of printed circuit boards to minimize electrical losses and interference, while the mechanical design office creates a design perfectly suited for integrating the boards into the final equipment. This synergy ensures optimal performance and long-lasting reliability.

Respecting Deadlines: A Key Challenge in Electronic Subcontracting

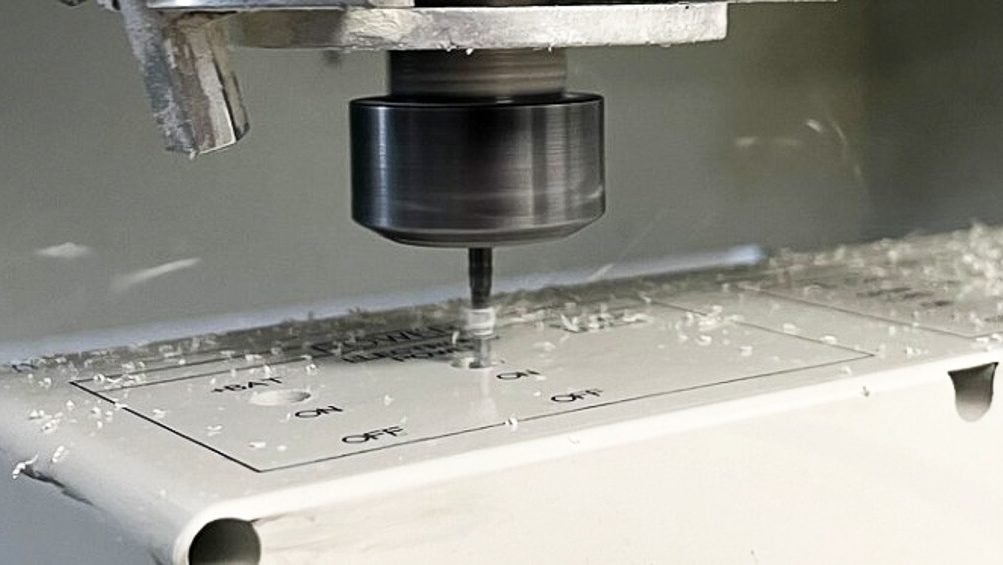

Rapid Prototyping and Controlled Industrialization

Some subcontractors, such as MCI, stand out for their ability to offer a wide range of complementary services. For example, MCI has developed recognized expertise in rapid prototyping and the manufacturing of bed-of-nails test fixtures — an essential tool for functional testing of electronic circuit boards. Thanks to these capabilities, our clients can quickly validate their prototypes before mass production, significantly reducing the risk of delays caused by late modifications. This approach helps optimize their productivity while ensuring deadlines are met.

Electronic Circuit Boards: A Strategic Lever for Industrial Success

Choosing a competent and committed electronic subcontractor is a true strategic asset. It guarantees not only reliable and high-performance products but also a high level of safety, which is essential in an industry where even the slightest failure can have critical consequences. Meeting deadlines, adaptability, and the quality of partnership relationships are all factors that foster long-lasting collaboration, helping to strengthen the company’s competitiveness and support its innovation.

Need reliable and high-performance services? We are here to support you!

Our expertise meets your needs in the development of your electronic systems. Our knowledge and efficiency drive your projects toward success.

carte électronique sur mesure, fabrication carte électronique, conception carte électronique, assemblage carte électronique, test carte électronique, prototypage carte électronique, industrialisation électronique, sous-traitant carte électronique, routage PCB, intégration électronique, carte électronique fiable, qualité électronique industrielle, contrôle qualité carte électronique, performance carte électronique, certification carte électronique, fiabilité électronique embarquée, conformité normes électroniques, sécurité des systèmes électroniques, carte électronique pour l’industrie, électronique embarquée industrielle, carte électronique pour l’automobile, solutions électroniques industrielles, électronique pour machines spéciales, électronique pour systèmes critiques, partenaire sous-traitance électronique, expert carte électronique, sous-traitance électronique France, services en électronique industrielle, bureau d’étude électronique, fournisseur carte électronique

Laisser un commentaire