Downloadable PDF Checklist

5 Key Points to Check Before Investing in an Electronic Test Bed (Bed of Nails)

Is it possible to produce more while reducing costs?

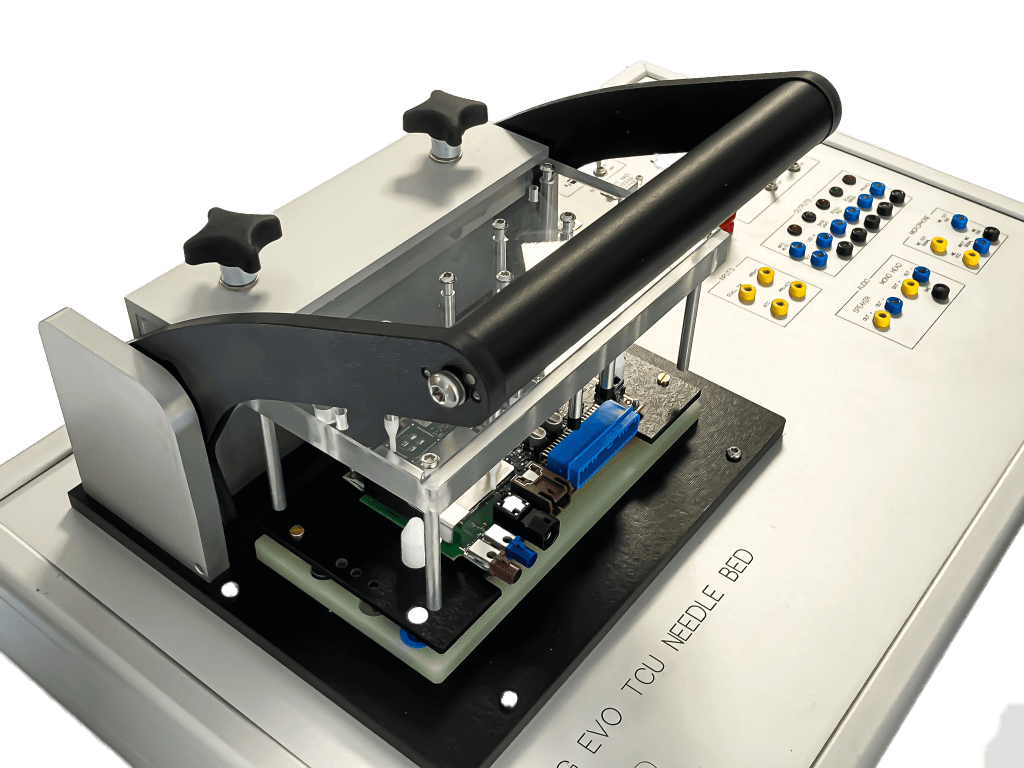

In a challenging industrial environment, companies in the electronics sector are more eager than ever to automate and secure their testing processes. To meet this demand, MCI offers a complete range of bed-of-nails test fixtures—true levers of efficiency. These often-overlooked technical tools enable significant time savings, reduced errors, and overall resource optimization.

Let’s explore why the bed-of-nails has become a strategic asset for better controlling production costs.

What is a bed of nails test fixture?

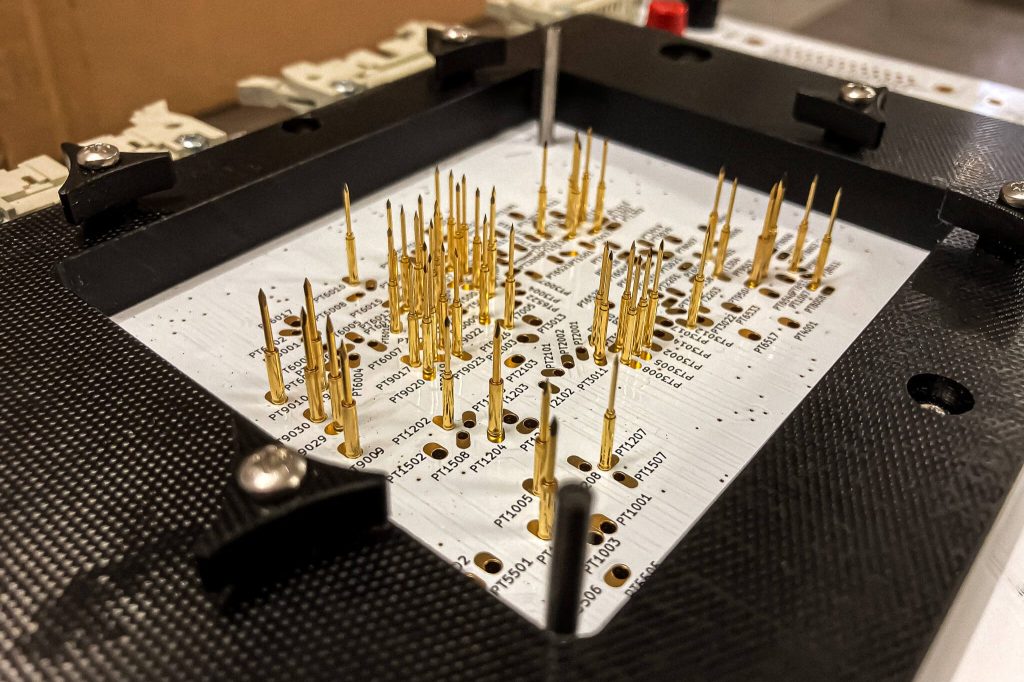

A bed of nails is a test bench used in industrial electronics. It allows for the analysis, programming, or inspection of a printed circuit board (PCB) or a fully assembled electronic board. There are several types of fixtures, each designed to meet specific testing needs.

At MCI, we design and manufacture four main categories of bed-of-nails fixtures:

- Test interface: A high-end, robust, and ergonomic model, ideal for repetitive production testing.

- Machined bed of nails: Perfect for prototyping and small production runs.

- Routed bed of nails: Designed for high-volume production, combining speed and precision.

- Custom bed of nails: Engineered to test complex boards with specific mechanical constraints.

All our bed-of-nails solutions are built to integrate seamlessly into production lines, ensuring maximum reliability during control and validation phases.

How do they help reduce costs?

Reduction of testing time

Thanks to test automation, the need for skilled labor is reduced. Defects are detected earlier and faster, which limits rework and losses at the end of the chain.

Fewer breakdowns, more reliability

A properly tested product is a less defective product. After-sales service returns decrease, customer satisfaction increases. Additionally, data collected from tests enables continuous improvement of the production process.

Reusability and durability

The tooling is optimized in the long term: the same nail bed can be used for multiple production runs. Easy to adapt and maintain, it can incorporate protective covers. Result: a quickly amortized investment.

A positive logistical impact

By integrating the nail bed into your industrial strategy, you facilitate planning, reduce buffer stocks thanks to more reliable production, and improve the ability to produce on demand.

Case study: a manufacturer who halved their testing costs

Company X, specializing in electronic components for the automotive industry, was facing significant additional costs related to the testing phase. The boards were tested manually, which required three full-time operators, extended the timelines, and increased the error rate.

Before the integration of a nail bed:

- Temps de test par carte: 8 minutes

- Coût mensuel en ressources humaines: 12 000 euros

- Taux d’erreurs non détecté: 2 %

After the integration:

- Temps de test par carte: 2 minutes

- Coût mensuel réduit à 5 500 euros

- Taux d’erreurs inférieurs à 0.2%

This resulted in a cost reduction of over 54% and a 60% increase in productivity.

Far from being just a technical accessory, the nail bed stands out as a strategic solution for manufacturers aiming to increase productivity while reducing costs.

Need reliable and efficient services? We are here to support you!

Our expertise meets your needs in the development of your electronic systems. Our knowledge and efficiency propel your projects toward success.

Electronics, Electronic Components, Printed Circuit Board (PCB), Electronic Subcontracting, Electronic Systems, Electronic Technologies, Electronic Design, Technological Innovation, Electronic Hardware, Electronic Production

Microcontroller, BGA (Ball Grid Array), SMT (Surface-Mount Technology), IoT (Internet of Things), Semiconductors, Electronic Sensors, Renewable Energy and Electronics, Embedded Systems, Power Supply, Lithium-Ion Batteries

Consumer Electronics, Automotive Electronics, Industrial Electronics, Medical Electronics, Communication Electronics, Power Electronics, Industrial Automation, Audio and Video Technology, Robotics and Electronics, Security Electronics

R&D in Electronics (Research and Development), Electronic Circuit Design, Electronic Prototype Manufacturing, Electronic Engineering Subcontracting, Electronic Equipment Repair, Circuit Testing and Validation, Electronics Consulting, PCB Design, Electronic Component Assembly, Rapid Prototyping in Electronics

Process Automation, Internet of Things (IoT), Blockchain and Electronics, Artificial Intelligence and Electronics, Sustainable Electronics, Smartphones and Electronic Components, 5G and Electronics, Embedded Technologies, Wearable Technologies, Green and Eco-Friendly Electronics

Electronics Market, Electronics Trends 2025, Future of Electronics, Electronics in Europe, Electronics Equipment Export, Electronics Manufacturing in Asia, Energy Consumption in Electronics, Electronics Startups, Fusion of Electronics and Technologies, Evolution of Electronic Materials

Laisser un commentaire